Undersea cables transmit 99% of all international data. There are currently more than 300 undersea cables, which have a combined length of 550,000 miles, which is long enough to circle the globe 22 times. The longest cable runs from Germany to Korea, has 39 landing points, and is 24,000 miles long. Some undersea cables are positioned as much as 25,000 feet below the surface of the ocean. The process of laying them may take several months to complete and can cost hundreds of millions of dollars.

History

The first commercial cable across the English Channel went into service in 1851. Beginning in 1853, additional commercial cable projects connected Great Britain with Ireland, Belgium, the Netherlands, and Denmark.

The first transatlantic telegraph cable was laid on the ocean floor between Valentia Island in western Ireland to eastern Newfoundland. The project to lay the cable took four years, from 1854 to 1858. Using that cable, transmission of transatlantic messages took only 17 hours as opposed to ten days by ship.

In 1863, a cable to Bombay (now Mumbai) provided a link to Saudi Arabia. By 1870, there was a link from Bombay to London; by 1872, a link to Australia from Bombay via Singapore and China; and by 1876, from the British Empire to New Zealand. From 1850 to 1911, Britain dominated the cable industry in the North Atlantic Ocean, and by 1923, British companies owned and operated two-thirds of the world’s undersea cables.

Listed below are historic dates for undersea cables across the Pacific.

- In 1902, cables established links from the US mainland to Hawaii, and additional links to Canada, Australia, New Zealand, and Fiji.

- In 1903, Guam and the Philippines linked to the US Mainland.

- Japan joined the network in 1906.

- A Hawaii–Japan connection occurred in 1964.

- In 1991, the first regenerative (repeated) system directly linked the US Mainland to Japan.

- Undersea Optical Cable Construction

Undersea optical cable construction varies according to the application, water temperature and depth, and cable manufacturer. The schematic shown below is from a Hexatronic Submarine Catalog. The model number is TOL 404 1051 GJMLTV, 15-ton DAL. This particular cable weighs 15 tons per mile, is used in depths less than or equal to 3,000 meters, and has a capacity of 12 to 96 optical fibers.

Schematic of a Modern Undersea Communications Cable

The schematic shows a double-armored, unitube cable for applications needing high protection due to ocean conditions. The optical fibers are free to move within the hermetically sealed, stainless steel sheath. A thixotropic water-blocking compound surrounds the fibers. The polyethylene sheath protects the stainless steel tube from water incursion. Two layers of galvanized steel wire protect against chafing and corrosion. The inner wire sheathing is made of small wires and the outer sheathing uses heavier wires. Mylar tape or a similar material covers these wire bundles. Finally, a polyethylene yarn wrap, impregnated with an organic material to prevent deterioration, completes the cable.

Cable weights vary from 2.5 to 60 tons per mile. The heavier cables are those that approach the shore because they need more armoring. Such installations use two wraps of galvanized steel wire as shown in the schematic.

Laying Undersea Cables

Before laying an undersea cable, it is important to perform a Desktop Study that encompasses many separate steps as follows.

- Obtain a route description

- Get information on landing sites

- Learn about geopolitical and cultural issues

- List security concerns

- Determine geology, meteorology, oceanography, fisheries, and hazards

- Understand permit requirements

The typical cost of an undersea cable installation is between $100 and $500 million, and the process requires a variety of steps:

- Coiling the cable into the installation ship takes three to four weeks.

- The end of the cable runs from the first landing station to several miles into the sea.

- The ship then begins the laying process.

- The cable feeds into a plow, which trenches the ocean floor and lays the cable.

After laying sufficient cable onto the ocean floor, the cable feeds into an open trench from the low water mark to the landing station. The cable enters the landing station through the floor and attaches to its circuitry. Dirt or other material covers the trench so the cable is not exposed.

Operational Considerations

Multiplexing

Pairs of optical fibers work together with each fiber transmitting in only one direction, and most modern cable systems use a transmission speed of 2.5 Gbps (gigabits per second) for each fiber pair. However, it is possible to send signals through fibers at four to eight different wavelengths. This results in capacity of 10 to 20 Gbps per fiber pair. Multiplexing is the process of transmitting signals in this manner.

Repeaters

When the optical signals travel over distances greater than 400 km, they become dispersed or attenuated. Repeaters amplify and reshape the degraded signals before transmission to the landing station.

Repeaters use solid-state amplifiers to process the signals. The repeaters require a direct current of 20 watts to operate. Repeaters are series connected and spaced at intervals along the cable run. Copper sheeting in the cables conducts power for the repeaters. Repeaters cost between $500,000 and $1 million each.

Cable Repairs

When a break occurs, each landing station tests the cable to determine the location of the break. A repair ship then travels to the spot of break and drops a mooring with a buoy attached to mark the location. Next, the ship moves a convenient distance from the break and drags the seafloor with a grapnel to locate the cable. When the grapnel hooks the cable, the ship stops moving forward. Then, picking machinery lifts the cable, secures it to a mooring anchor, and workers cut the cable. They stow the short end of the cable on the ship. Workers test other end of the cable to determine its condition. If it is good, electricians splice it to a length of spare cable aboard the ship. They protect the splice with heavily tarred jute yarn. Next, the ship moves back to the location of the break, paying out cable as it goes. When it reaches the break location, it will then lift and test the other end of the cable. If that end is in proper condition, workers splice the two cable ends together. This splice is also protected with heavily tarred jute yarn, and the cable is laid as close to its original position as possible.

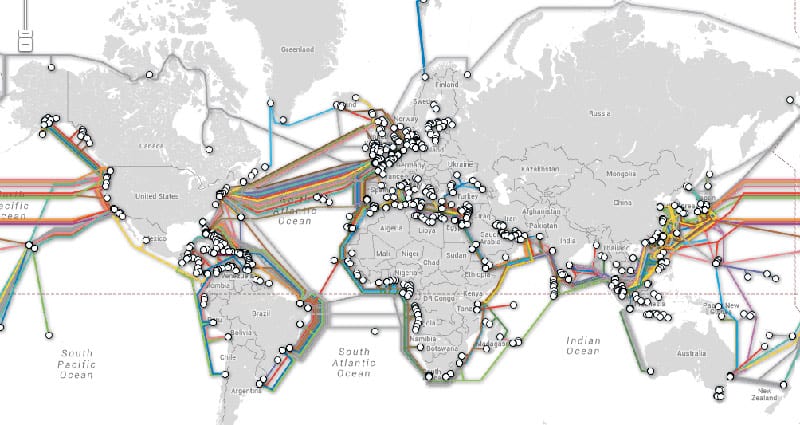

Submarine Cable Map

TeleGeography’s website, https://www.telegeography.com/, has a link to its free Submarine Cable Map. The map shows active and planned submarine cable systems and landing stations. The map is interactive, and one can select a cable from the list and get the cable’s profile, which has the following information.

- Cable name

- Ready-for-service date

- Length

- Owners

- Website

- Landing Points